Homemade Ricotta recipe created with America’s Dairy Farm Families and Importers, in partnership with the Innovation Center for U.S.Dairy, however, the views and opinions included are my own. One of the things I enjoy most about being a blogger is the chance to visit places to which I normally wouldn’t think. So, I was not going to pass up the invitation to visit a dairy farm in my state.

One of the things I enjoy most about being a blogger is the chance to visit places to which I normally wouldn’t think. So, I was not going to pass up the invitation to visit a dairy farm in my state.

Especially if it's in an area of Texas I've never been before. Wildcat Dairy Farm is in central Texas. It's a family-run business where the owners Frank and Annette emigrated from Luxembourg in search of new opportunities, bought Wildcat during the ‘90s, and rescued the dairy farm from bankruptcy. Over the years, they have expanded it and streamlined many of the processes, with 2 of their children currently working on the farm as well.

Currently, they own 4200 Holstein dairy cows, who are milked twice a day and on average each cow produces eight gallons of milk.

I was curious to know how dairy production manages to supply fresh milk and cream to grocery stores around the USA. I grew up drinking shelf-stable milk, which is still safely processed and handled, but I prefer fresh milk because to me it’s more flavorful. In the USA, milk is pasteurized at lower temperature, as opposed to shelf-stable milk, which does not require refrigeration and is pasteurized at high temperature. This translates into more careful handling of the milk, which is analyzed and tested several times during the on-farm collection and distribution processes. They check the milk for micro organism and antibiotic contamination. Dairy farmers are careful not to send contaminated milk to the plants because they can be banned for repetitive offenses, is a well-supervised process. The farm we visited is among the ones that supply products to the store three blocks away from my house. (I was excited to learn this) And in general, it takes less than 48 hours for the milk to reach the store, which is amazing!

On the day of our visit, mid-August in Texas, with temperatures ranging 38-40C ~100F we could see first-hand the devotion that the family has for its cows. At Wildcat Dairy Farm they have 3 barns:

- Milking barn: with a high-tech carousel where 72 cows are milked simultaneously in less than 10 minutes. The udders are sprayed with sanitizer, cleaned with a cloth, and a first extraction is done manually to check that everything is in order, and then each cow is connected to the machine suctioning milk. Cows are milked twice a day and on average 365 days a year. They spend approximately 2 hours a day in the milking barn.

- Crossvent barn: here they are fed, they can socialize and ruminate to their heart's content. The cows spend 22 hours a day in this barn. This was my favorite barn because, despite the summer heat, it's held at 60F all year round. A content and relaxed cow produces more milk. We saw many innovative practices at the dairy; one was a robot that keeps food at the cows' reach (like a giant Roomba). The cows have fresh water, humidifiers and even artificial rain to keep them cool. The cows are managed in this farm in groups. We learned that cows have social dynamics with groups and hierarchies that determine for example who eats first. But separated according to affinity and other considerations, in this barn they roam free and can lie down next to their friends. There is plenty of natural light, which is supplemented with LED lights that are turned off at night. The food they receive is periodically adjusted to make sure they receive a balanced diet between grains, grass or fodder.

- Birthing barn: where the birthing cows and their newborn calves stay. I was impressed to see that calves receive colostrum. The farmers have observed how important it is for the health of young calves. In this barn, they are staffed 24 hours a day.

What else did we learn? The milk from the milking process goes through a large particle filtration system and immediately it is cooled in a system similar to a refrigerator or car radiator. The heat extracted from the milk is used to provide the farm with hot water (milk from the cow is 38C or 101F. It is cooled to 1C) and is transferred from the storage tank directly into one of the transport trucks. The trucks are so well insulated that there is only a one-degree change over a 24 hour period, an incredible technology which contributes to energy and fuel savings. Milk from this farm travels less than 4 hours to the processing plant, but the tank may keep it cold for a much longer period.

At the plant, milk is pasteurized and homogenized, some go to the production of other products such as butter, cheese, cream, and the rest is packaged for delivery.

We also visited the barns where they store the food for the cows, and the lagoons they use to manage animal waste, which is reused to fertilize the fodder crops on the same farm.

Finally, we were invited to their office, and we enjoyed Annette's delicious baking. Her cheese kuchen was identical to this recipe; I could not believe it. She also made a smoothie, and we tasted different kinds of milk, which are available in the market: shakes and high-protein alternatives. And homemade yogurt, cheese—everything was delicious.

My visit to the farm was a great experience. It's amazing to see how in such a large dairy barn, all details have been considered. Congratulations to the Volleman family! There is a lot to learn about our dairy farmers, for more information go to UndeniablyDairy.org.

This home-made ricotta is very simple, I made it with lemon juice, but there are other alternatives to curdle milk. Salt provides flavor, but the result is neutral, if you want to eat it on toast, I recommend adding more salt. Or, you can always season it later to use in recipes such as:

- Spinach Ricotta Stuffed Crepes

- Or serve seasoned over a vegetable cream such as this Cream of Mushrooms

Homemade Ricotta

Yields 1 cup

Ingredients:

- 2 liters fresh whole milk, not pasteurized at high temperature or UHT

- ⅓ cup lemon juice (or white vinegar or ½ teaspoon citric acid)

- 1 teaspoons salt

Preparation:

- Put the milk in a medium pot over medium heat. Cook until milk reaches a temperature of 200F or 94C. It must not boil, it should give steam and a little froth. In my case, it took 15 minutes.

- Add lemon juice and salt, stir. Allow resting for 10 minutes for curd to separate.

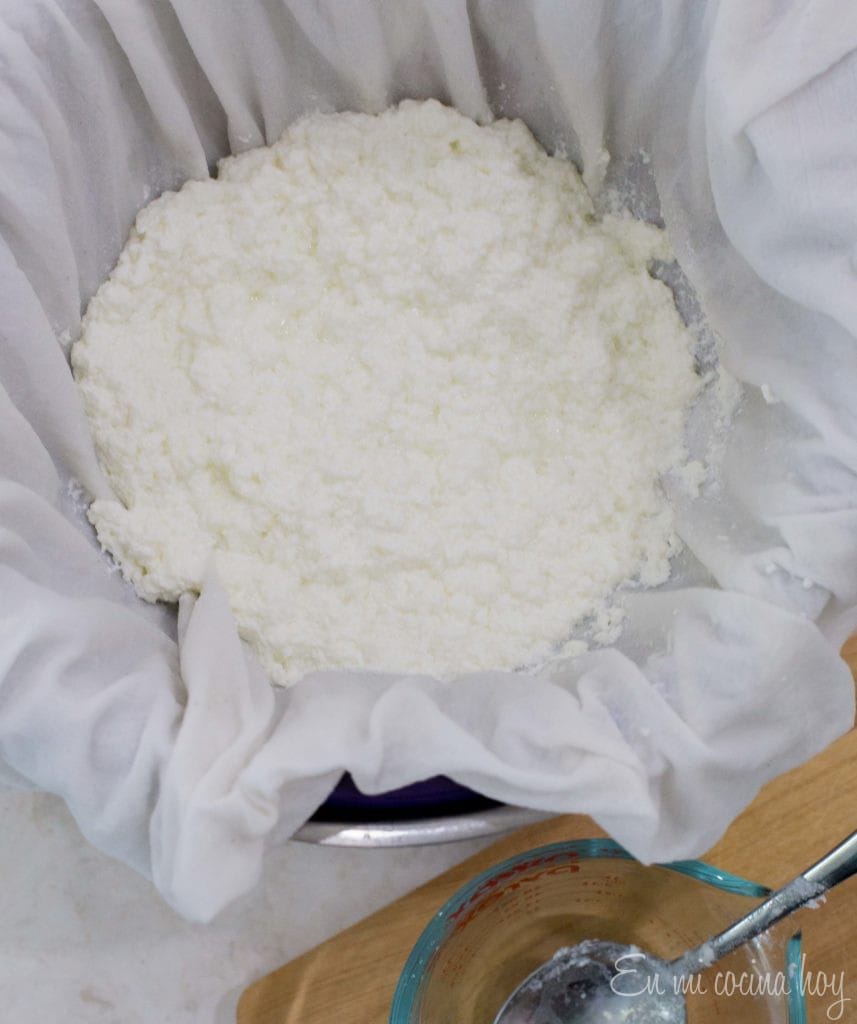

- Place a wet medium-weave kitchen towel, over a sieve and the sieve into a pot. Empty the curd, stir; you can taste it and decide whether it needs more salt. Allow to drain for 30 minutes and then hold the ends of the cloth together and squeeze. You can decide how moist the ricotta will be (leave a little more wet than the commercial one, because it will dry some during cooling). Always save some of the serum in case the ricotta is too dry.

- Place in a bowl and serve or refrigerate for up to 1 week.

You can use the serum as a base for vegetable cream, or to make bread, pound cake, etc.

This post is created with America’s Dairy Farm Families and Importers, in partnership with the Innovation Center for U.S. Dairy. However, the views and opinions included are my own.

This post is created with America’s Dairy Farm Families and Importers, in partnership with the Innovation Center for U.S. Dairy. However, the views and opinions included are my own.

Leave a Reply